INNOVATING THROUGH

ADVANCED COMPETENCE

Amphenol AUTOMOTIVE is gonna putting here a nice introduction for the products categories –

just a few simple sentences about the whole overview of the products.

AMPHENOL

AUTOMOTIVE COMPETENCIES

At Amphenol Automotive, we are committed to delivering high-performance solutions that meet the evolving needs of the automotive industry. Our extensive portfolio of competencies spans stamping, machining, plating, molding, component assembly, cable & harness assembly, electronic manufacturing, engineering, and prototyping.

With a presence in over 35 advanced manufacturing facilities worldwide, our 15,500-strong workforce combines global expertise with local excellence to provide innovative and reliable automotive components. Discover how Amphenol Automotive’s state-of-the-art technologies and dedicated engineering teams can drive your projects forward with unmatched quality and efficiency.

ADDITIONAL INFORMATION

DELIVERING RELIABLE COMPETENCIES

FOR AUTOMOTIVE NEEDS

Amphenol Automotive combines advanced manufacturing processes with engineering expertise to deliver solutions tailored to the automotive industry. With a strong global presence, we focus on precision, efficiency, and adaptability to meet diverse project requirements.

From stamping and machining to electronic manufacturing and prototyping, our capabilities enable us to support clients at every stage of development. By leveraging innovative technologies and skilled teams, we help bring ideas to life with a focus on quality and reliability.

SUPPORTING AUTOMOTIVE INNOVATION

THROUGH DIVERSE COMPETENCIES

Amphenol Automotive’s broad range of competencies ensures we can address the varied demands of automotive projects, no matter the complexity. With advanced facilities and a dedicated team, we provide solutions that align with the industry’s needs.

Explore our core competencies below to see how we can support your projects:

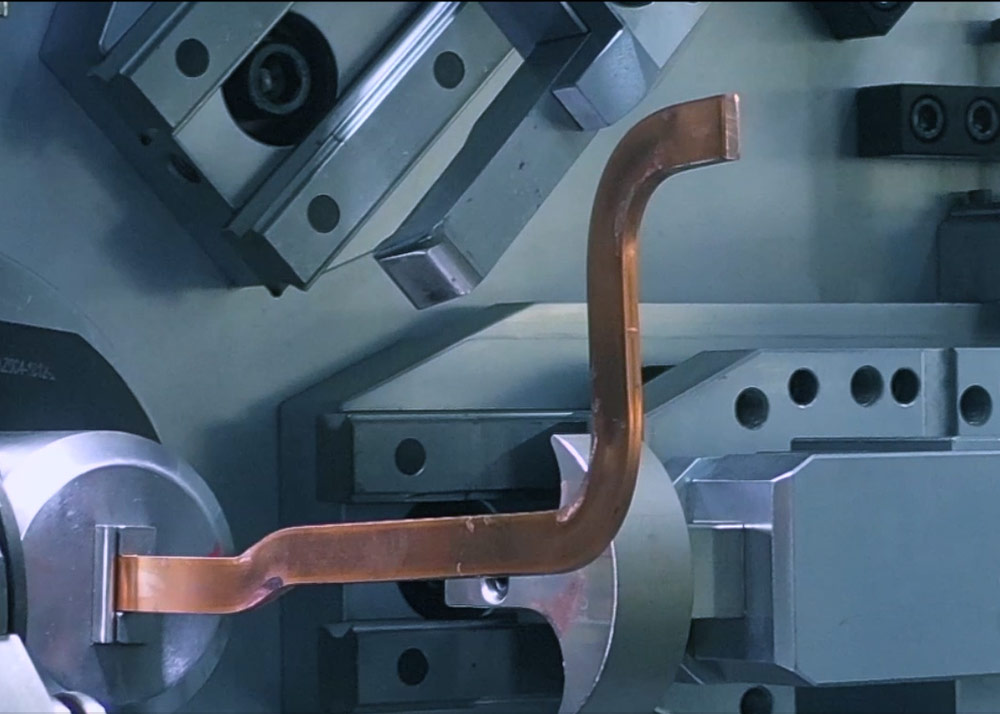

- Stamping: Precision processes for deep-drawn components and assemblies.

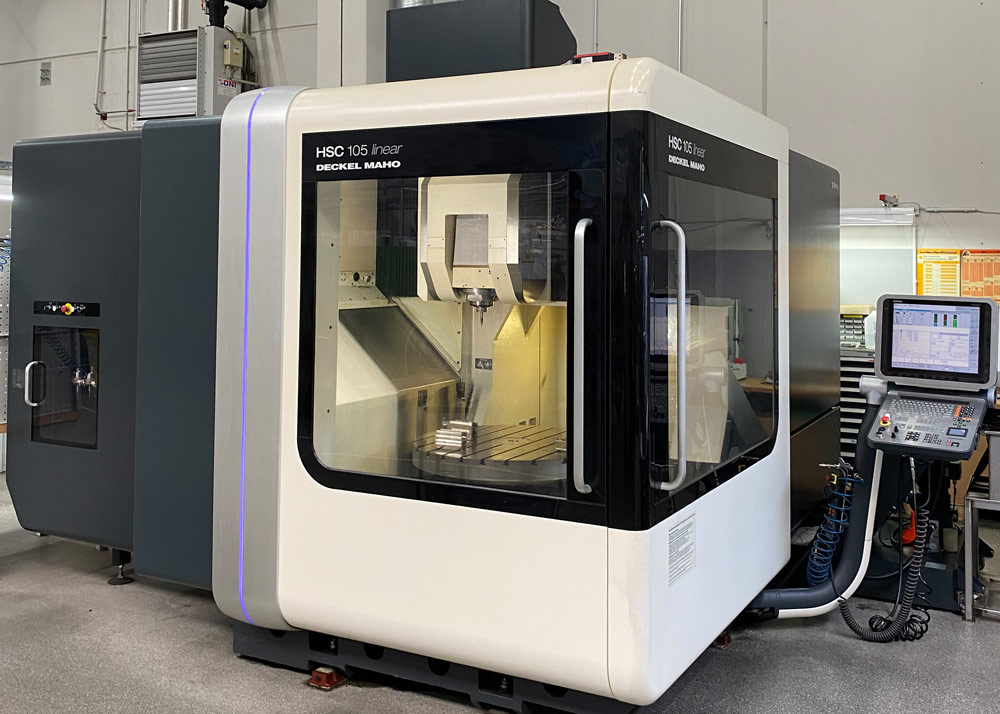

- Machining: Advanced techniques for forming precision parts and busbars.

- Plating: Reliable surface finishes through reel-to-reel and bulk plating.

- Molding: Bi-component, clean room, and over-molding solutions with high-performance materials.

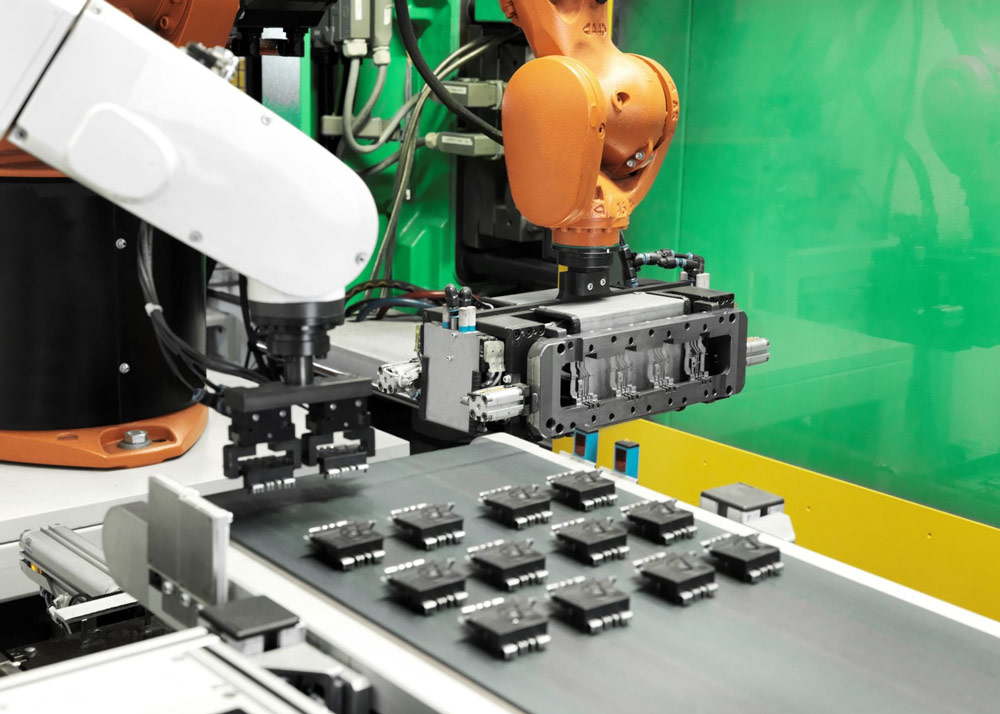

- Component Assembly: Automated production with smart technology integration.

- Cable & Harness Assembly: High-quality assemblies for secure and efficient connectivity.

- Electronic Manufacturing: SMT production, box builds, and clean room environments.

- Engineering: Design, testing, and simulation services for innovation and performance.

- Prototyping: Agile development through rapid prototyping and CNC machining.